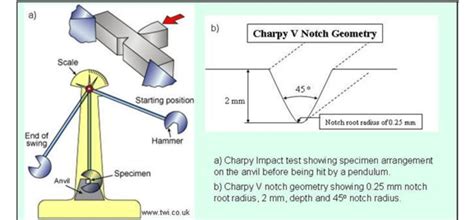

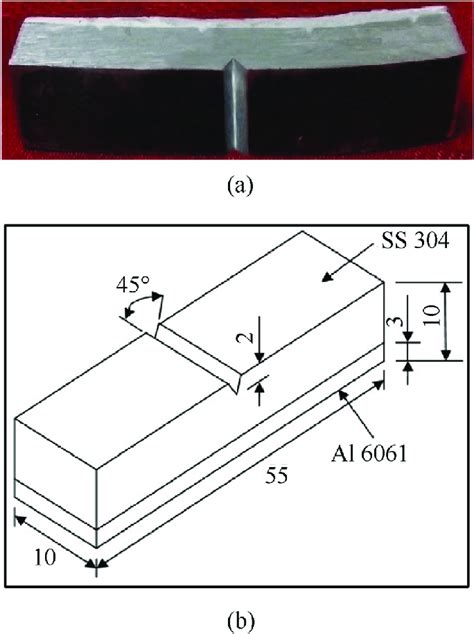

charpy impact test specimen geometry|charpy impact test sample : solution The standard Charpy impact test specimen is of dimension 55 mm × 10 mm × 10 mm, having a notch machined across one of the larger dimensions, as illustrated in Fig. 1.3. The Charpy .

WEBSearch the world's information, including webpages, images, videos and more. Google has many special features to help you find exactly what you're looking for.

{plog:ftitle_list}

Catarina Paolino nua + Informações. Catarina Paolino nua povd banho de vapor fodase com o russo magro. Xxx-hd. Vídeos Relacionados. HD. 8 min. Catarina paolino onlyfans . HD. 2 min. Catarina paolino grátis . HD. 3 min. Catarina paolino onlinfans . HD. 9 seconds. Catarina paolino olinfans . HD. 8 min. Paolino catarina . HD. 6 min.

Charpy impact testing is a low-cost and reliable test method for measuring the impact resistance of materials and is commonly required by construction codes for fracture- critical structures .The Charpy V-notch impact is a mechanical test for determining qualitative results for material properties and performance which are useful in engineering design, analysis of structures, and . The determined Johnson-Cook constitutive parameters (A = 582.67 MPa, B = 582.47 MPa, n = 0.438 and C = 0.044) and partial damage parameters (D 1 = −0.06248, D 2 = .measure the resistance to crack growth, the Charpy impact test remains, as it gives a simple inexpensive method of classifying a materials resistance to brittle fracture. Nowdays, the .

The Charpy impact test. The securely clamped standard size specimen is hit by a pivoting "hammer" with a pointed edge. The inset shows the specimen geometry. In order to do this .The standard Charpy impact test specimen is of dimension 55 mm × 10 mm × 10 mm, having a notch machined across one of the larger dimensions, as illustrated in Fig. 1.3. The Charpy .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a . This paper provides a critical review of existing applications of the Charpy method for impact testing of cementitious composites. Studies have employed various specimen .

Download scientific diagram | Geometry of the Charpy impact test specimen (modified DVN specimen) as proposed by the present study for impact testing of TMT rebar: (a) and (b) Top view, (c) and (d . The results show that pendulum velocity has negligible influence on Charpy impact test results; the maximum force and impact absorbed energy both have a highly linear relationship to specimen width; Charpy impact test is sensitive to striker geometry, the results measured by 2 mm-striker are obviously smaller than those of 8 mm-striker.

charpy v notch sample size

According to current Charpy test standards (ASTM E23-12c and ISO 148-1:2009), absorbed energy (KV) results from partially fractured test specimens can be averaged with the results from fully fractured specimens. However, most researchers agree that if a specimen does not fully fracture at the end of a Charpy test, a significantThe Charpy impact and notched impact test to ISO 179-1 and ISO 179-2 provide characteristic values for impact strength at high strain rates in the form of an area-related energy value. The tests are normally performed in normal climate or at low temperatures. Applications include: The comparison of different molding materialsThe effect of specimen size and geometry on the ductile-to-ductile transition temperature is more difficult to predict, although the available data suggest a simple shift in the transition temperature due to specimen size changes.The relatively shallower notch used in smaller specimens alters the deformation pattern, and permits yielding to .Charpy V-notch testing of linepipe steels is carried out according to ASTM E23 (American Society for Testing of Material) [6]. The standard full-size specimen (10 mm × 10 mm × 55 mm, a 45° V .

The most common notch geometry today is the V-notch, but other geometries are or have been sometimes used. Depending on notch geometry, the test is known as the Charpy-V impact test (CVN) or Charpy-U impact test (CUN) or even Charpy-keyhole. The U-notch has normally a radius of 1 mm, compared to the V-notch which has a root radius of 0.25 mm.The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient .

Charpy impact testing is a low-cost and reliable test method for measuring the impact . such as specimen size, notch geometry, machine anvils, and striker configuration, and, to a lesser degree, impact velocity, energy losses, and friction.6 Charpy testing is often specified as an acceptance test for structural materials. Reliable measurements of Description 31 papers cover three wide-ranging topics: • unique small and miniature specimens, as well as nondestructive, nonintrusive, and in-situ test techniques for measuring mechanicals and .In order to develop the small specimen technology in Charpy impact testing, the effects of V-notch dimensions on the test results were investigated for miniaturized specimens of a ferritic steel, Japanese Ferrite/Martensite Dual Phase Steel (JFMS). The miniaturized Charpy specimens had four different square cross-sections of 3.3, 2, 1.5 and 1 mm, and each of them .

Understanding the critical importance of Charpy Impact Testing sets the stage for delving into its step-by-step procedure and intricacies – an insightful journey that demystifies this essential method for assessing material toughness. Step-by-step Procedure of a Charpy Impact Test. Performing a Charpy impact test involves several important steps.In a Charpy impact test to ISO 148-1, a notched metal specimen is severed using a pendulum hammer. For the test, the metal specimen is centered on the supports in the pendulum impact tester. The notch is exactly across from the point at which the pendulum hammer strikes the specimen. This impact test is used to determine the absorbed impact energy.The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. . In some circumstances, sub-size Charpy specimens can be tested with thickness less than 10mm. The specimen is supported at its two ends on an .

7.2 Stress distribution at notch tip of a Charpy specimen 7.2.1 CHARPY SPECIMEN GEOMETRY Since the above studiestok place different kinds of Charpy specimens have been used. The most well known are presented in figure 7.2 and in table 7.1. In this table the specimen notch is defined by the notch radius U the notch angle \ and the notch depth a.LI H., ZHOU X., XU W, Correlation Between Charpy Absorbed Energy Using 2 mm and 8 mm Strikers. J. ASTM Int. 2011 October, 8 (9) [JAI] [8] NANSTAD R.K., SWAIN R.L, BERGGREN R.G, Influence of thermal conditioning media on Charpy specimen test temperature. Charpy Impact Test: Factors and Variables, ASTM STP 1072. ASTM, 1990, pp. 195.

charpy impact test sample dimensions

The Charpy impact test is performed to evaluate the resistance of the metal to breakage by flexural shock or impact load according to standard test method ASTM D6110. . Charpy test specimens normally measure 55x10x10mm and have a notch machined across one of the larger faces. The notches may be : V-notch – A V-shaped notch, 2mm deep, with .

The Charpy impact test is carried out in a 3-point flexure setup.The Charpy specimen is centered on the supports in the pendulum impact tester and rests against two anvils. In the case of notched specimens, the notch faces away from the pendulum hammer and is placed exactly across from the point at which the hammer strikes the specimen.

Explore the Charpy V-notch impact test, a standard measure of a material's impact energy during fracture. . Specimen (e.g. notch geometry, inhomogeneous distribution of atoms during the early stages of nucleation, duplex grain structures including both coarse and fine grains lead to inconsistent energy distribution, chemical composition .The inset shows the specimen geometry. In order to do this right every time, you fix your hammer at a point just above your specimen around which it can rotate freely. . When we do just a simple Charpy impact test and measure the impact fracture energy at different temperatures for one kind of material (again, far easier to do than with more .IfEP is an accredited producer of certified reference materials for tensile test and Charpy pendulum impact test. . Flat test specimen: Tensile strength levels : 300 – 800 MPa; Certified parameters: Rp 0,2, Rm, A; Round test specimen: Tensile strength levels: 500 – 1000 MPa; Certified parameters: Rp 0,2, Rm, A, Z; Specimen geometry:Question: You were determining the Charpy impact strength for Your polyethylene material. You used hammer with 5J energy and standard impact test specimen (see slide 23) with notch (notch depth 1,2 mm). 64 % of the hammer energy was consumed for breaking the sample; what was the impact toughness of Your PE-material?

An impact test consists of a striker hitting the test specimen to transfer a large force in a short time.You can use a drop tower or a pendulum tester to achieve such large forces.. A striker is dropped vertically from a height for a drop tower test and uses gravity to achieve the necessary impact energy. Similarly, in a pendulum test, the striker is fixed to an arm that swings like a .

The impact energy A k, a value measured by the Charpy impact test, . In this way, the influence of specimen geometry to impact energy is extracted, and a new mechanical property to describe the impact load-bearing capability of a material is defined. Finally, the regression analyses based on impact test results of two kinds of steel were .The Charpy impact test is a simple test designed to evaluate materials under dynamic loading conditions. ASTM E23‐07 í, Standard Test Methods for Notched Bar Impact Testing of Metallic Materials, outlines the test method as well as specimen size and geometry. Typically, Charpy The specimen geometry has a significant influence on the Charpy impact strength. This is often a problem when it comes to the analysis of materials that can only be prepared with a curved shape .

The impact properties of an oxidized and a hydrogenated Zircaloy have been studied with an instrumented Charpy machine by using a strip Charpy V-notch specimen (1 mm thick by 4 mm wide).

charpy impact test sample

charpy impact test pdf

horário de Brasília. 06:50. É de Casa. Visite o site. Maria Beltrão, Rita Batista, Thiago Oliveira e Talitha Morete comandam programa de variedades das manhãs de sábado, .

charpy impact test specimen geometry|charpy impact test sample